Equipment and Tooling

Service

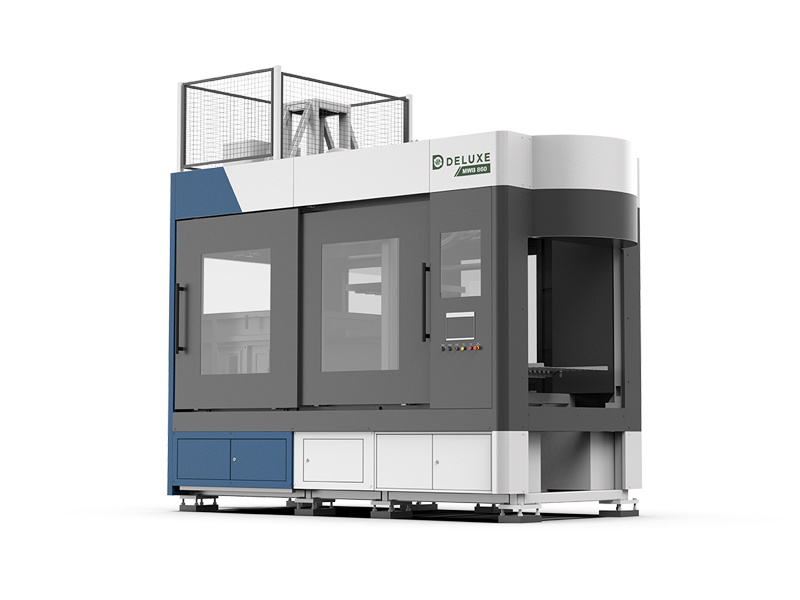

Automatic Pulp Molding Packaging Machine - MWB1311

Innovative technology

- Patented molding equipment technology, suitable for product height of less than 80mm

- Realizes mass production of products with draft angle less than 1.5 degrees

Yield improvement

- Improves traditional equipment structure, reduces mold quantity, cost, and lead and installation times

- Automated complete tooling wash, improving forming yield without affecting slurry concentration

Lower energy consumption

- Double-layered heat insulation design, reducing heat loss and energy waste

- Lowers electricity consumption by 7-10%, reducing production costs and carbon emissions

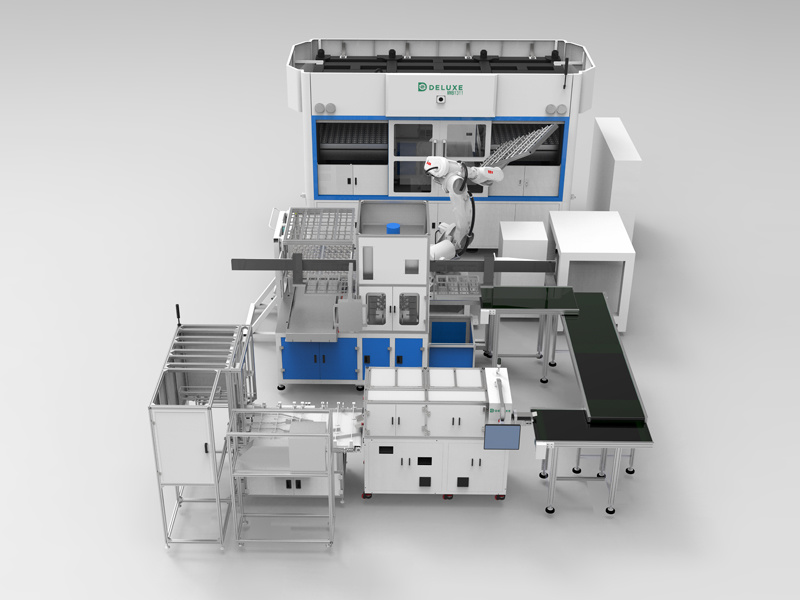

Efficiency improvements

- Daily production capacity as high as 1.0 to 1.5 tons

- Fully automated production – trim, inspect, stack, package, all in series – saving on labor

- Gains lead to more competitive product pricing and better product quality

Category:

| Application | Food Container Packaging, Industrial Packaging |

| Machine Dimensions | L6,280mm*W3,030mm*H3,800mm (not including Hydraulic station and robot arm ) |

| Tooling Dimensions | L1,300mm*W 1,100mm |

| Machine Weight | approx. 33tons |

| Maximum Product Height | 80 mm |

| Hot Press Maximum Pressure | 60 tons |

| Hot Press Plate Parallelism | ≤0.3mm |

| Hot Press Plate Lateral Precision | ≤0.06mm (with servo motor and screw system) |

| Main Hydraulic Valve | Taiwan Yuken, Taiwan Winner |

| Robot Arm | Kawasaki or Yaskawa |

| Servo System | Inovance |

| Control Components | Siemens or equivalent specifications; program can be modified with remote module |

| Total Rated Power | 293kW (electric heating) (Production power is about 60%) |

| Daily Capacity | 800-1300kg (Industrial products); 1000kg~1500kg ( food container packaging) |

Related Products