Equipment and Tooling

Service

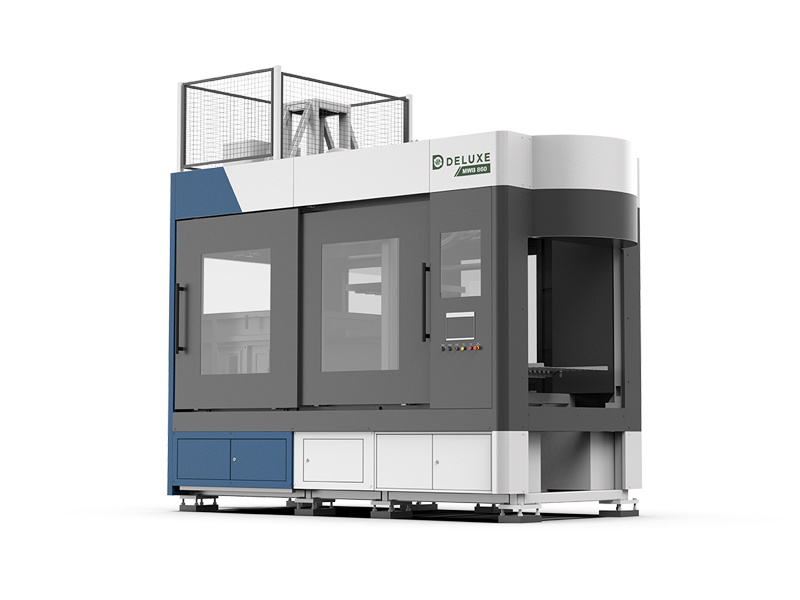

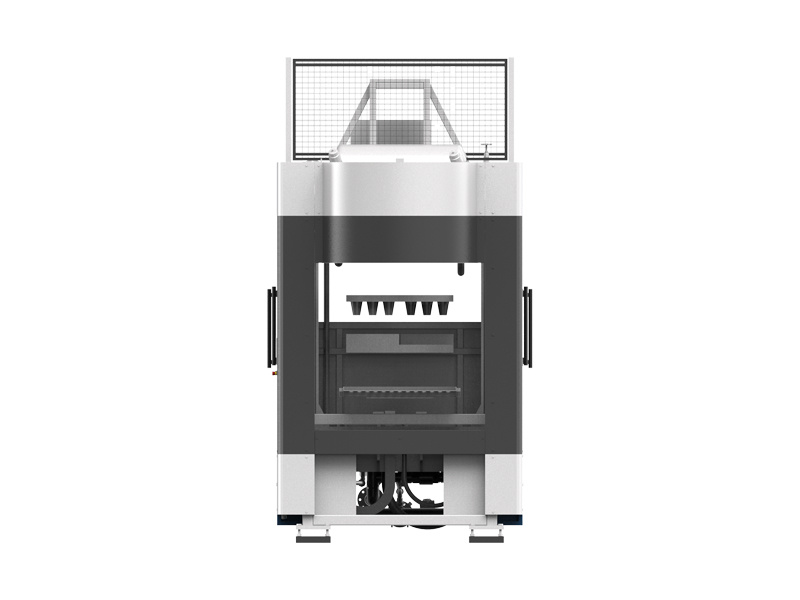

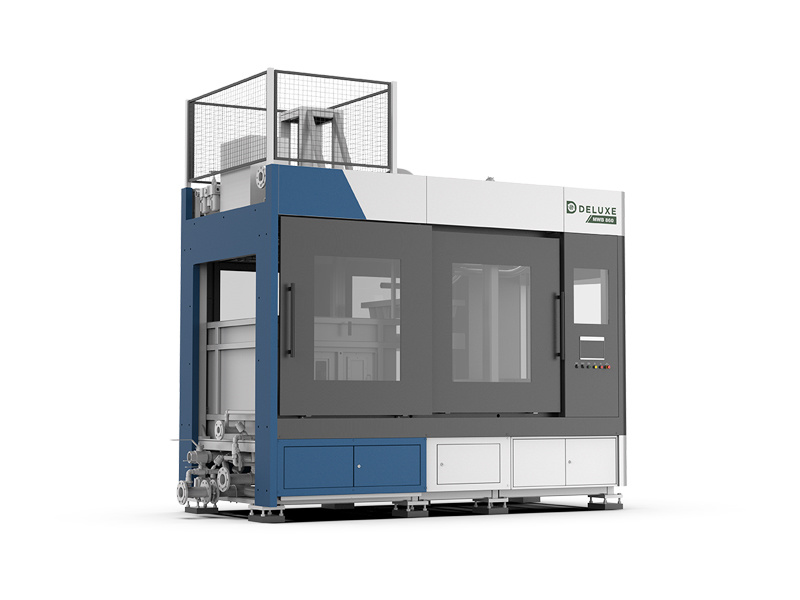

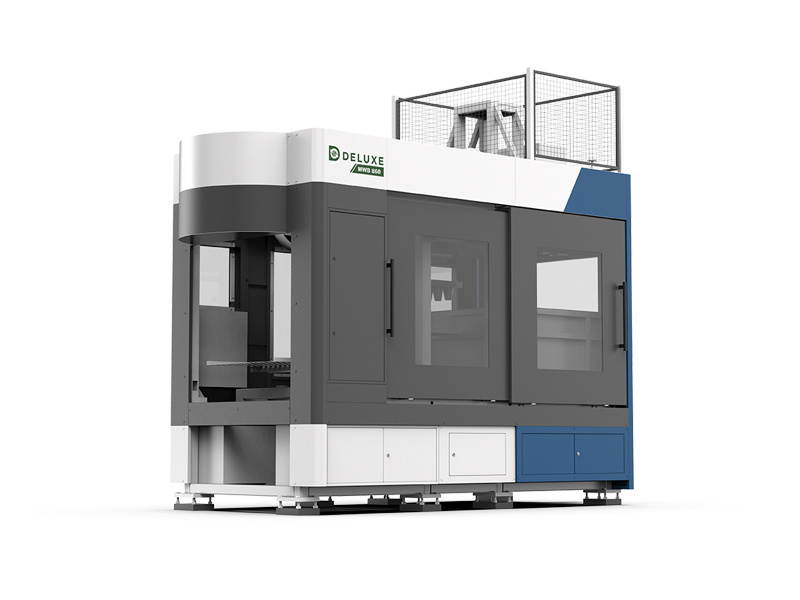

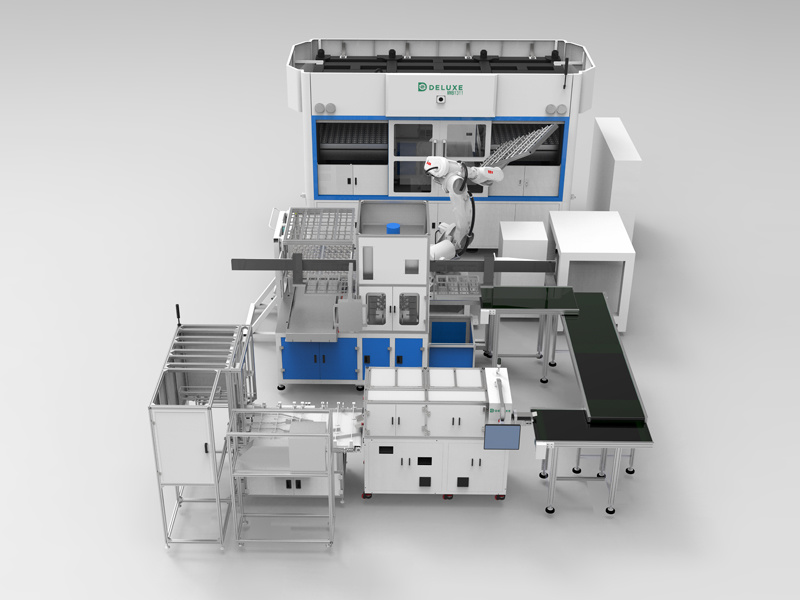

Automatic Pulp Molding Packaging Machine - MWB860

Achieve Exquisite Packaging with High Yield Output

- High precision requirements for the entire machine, balancing mass production yield and output

- Capable of producing products with exquisite surfaces, draft angles smaller than 0.5 degrees, or a height of 120mm

Highly Automated, Balancing Safety and Human Efficiency

- Through detailed production parameter control settings, achieve one operator handling 3 to 5 machines

- Can link edge-cutting, material collection, and packaging equipment to realize full-line automation

Save Production Energy Consumption

- Patented equipment design optimizes thermal energy usage efficiency, effectively saving energy consumption

Short Investment Return Cycle

- Optimized production process, mold investment can save approximately 15%

- Single machine production efficiency increased by 25%, significantly shortening the investment return cycle

Category:

| application | Food packaging, industrial packaging |

| Machine Dimensions | 4,380 x 1,830 x 3,410mm |

| Tooling Dimensions | 860 x 660mm |

| Machine Weight | approx. 9 tons |

| Max. Product Height | 120 mm |

| Hot Pressing Pressure | 30 tons (Hydraulic) |

| Forming Pressure | 5 tons (Hydraulic) |

| Total Power | 64KW |

| Total Electric Heating Power | 45KW |

| Rated Input Voltage | Three-phase five-wire 380V |

| Rated Frequency | 50-60HZ |

| Server System | Inovance |

| Controller | Siemens PLC Controller |

| Touch Screen | Kunlun Tongtai 10” Color Screen |

| Low Voltage Electrical Components | Schneider |

| Power Regulator | Yangming |

| Hydraulic Valve | Taiwan YUTIEN |

| Production Capacity | approx. 200 - 300 kg/day (Varies depending on product spec.) |

Related Products